09.2023 Office Talk

Ji Yuan Textile Industry (Shanghai) Safety Production Month 2023

Yuanfang Industry (Shanghai) / Pan Zhenzhen

Far Textile Industry (Shanghai) held the "Safety Production Month" event in June 2023, and made specific arrangements in advance under the guidance of President Zeng Zhuxian. Not only did it convey the importance of the event in management meetings, but it also fully created the atmosphere of the event in safety meetings for all employees. In addition, it also created special promotional columns, hung promotional banners, and used WeChat, electronic screens, and other methods, Communicate activity arrangements and safety production knowledge.

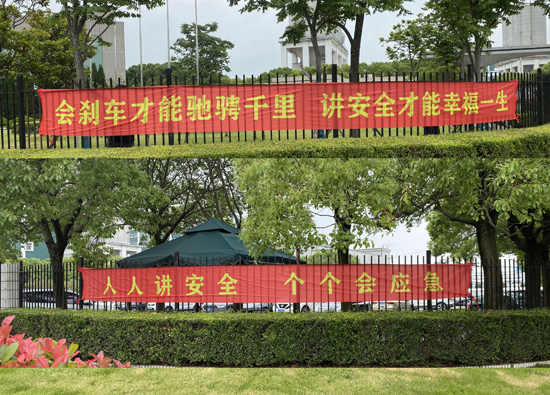

Far Textile Industry (Shanghai) held the "Safety Production Month" event in June 2023, and made specific arrangements in advance under the guidance of President Zeng Zhuxian. Not only did it convey the importance of the event in management meetings, but it also fully created the atmosphere of the event in safety meetings for all employees. In addition, it also created special promotional columns, hung promotional banners, and used WeChat, electronic screens, and other methods, Communicate activity arrangements and safety production knowledge. The goal of this' Safety Production Month 'is to' everyone speaks safety, everyone is capable of emergency response '. The planned activities and implementation results are as follows:

The goal of this' Safety Production Month 'is to' everyone speaks safety, everyone is capable of emergency response '. The planned activities and implementation results are as follows:1. Fire knowledge training and practical operation of fire extinguishers

On May 29th and 30th, a fire knowledge training program was held to introduce the types of accidents, basic knowledge of fire equipment, and key points for escape. Additionally, fire extinguisher drills were conducted for new employees in each department to enhance their fire safety protection capabilities.

2. Theme Emblem

From May 16th to June 5th, a solicitation activity was held, and a total of 31 employees' submissions on safety awareness were received. After preliminary evaluation by the company, they were submitted for publication in the group's publications.

3.6.5 Environmental Day - Plastic Reduction and Pickup

In response to Environmental Day on June 5th, employees were invited to use waste plastic products to remake them into environmentally friendly works. A total of 13 finished products were received, which not only cultivated environmental awareness but also enriched colleagues' leisure lives.

4. Online answers to safety production knowledge

From June 8th to 9th, an online Q&A level for safety production knowledge was set up, allowing employees to scan and answer through their mobile phones. Red envelopes were distributed to motivate all employees to participate, resulting in 572 valid responses (≥ 60 points, 100 point system) with an average score of 91 points.

5. Find fault for hidden dangers

On June 14th, two unique "Hidden Danger Finding" activities will be held. Participants must randomly select images from the "Production Hazard Atlas" and quickly identify the safety hazards. Colleagues and contractors warmly support and participate.

6. Fire escape cabin

On June 15th and 16th, the "Fire Escape Cabin" simulated escape activity was launched, inviting participants to enter the escape cabin, cover their mouth and nose according to the escape signs, lean forward, and choose the correct channel to escape from the fire. The company distributes wipes to each participant, emphasizing the essentials of escape and encouraging everyone to learn emergency escape skills.

7. Comprehensive emergency drill

On June 29th, a "comprehensive emergency drill" was held to simulate a fire incident caused by the leakage of HP on the 22nd line of the 4th floor of the polyester cotton front spinning factory. The drill included reporting, firefighting, rescue, evacuation, power outage, and environmental monitoring, to test the rescue and response capabilities of various departments of the staple fiber industry in response to emergencies, strengthen emergency response linkage, and enhance the comprehensive capabilities of early warning, response, coordination and command, and post disaster recovery in response to emergencies. Representatives from all departments of the factory were also sent to observe and guide, and through on-site implementation and video broadcasting, practical exercises and desktop exercises, local offices and the entire factory worked together to successfully achieve the task, while sorting out various parallel preparation plans.

The safety month will eventually pass, but the improvement and enhancement of safety production will never end. Only by being diligent, always following regulations, and treating every day and month as a safety day and month, can we ensure the safety of all employees. Through this event, the safety measures of all personnel have been implemented from theory to action, and various departments have also collaborated and integrated resources in the process to build a solid team that can safeguard the company's safety production.

#