06.2021 Office Talk

Emergency drill for leakage of hazardous chemicals OTIZ

Oriental industries (Suzhou) / Zhang Yankun

Since I took over the management of chemical warehouse, I have been thinking about how to really strengthen the safety protection awareness of operators, so as to timely control and properly handle the sudden leakage of hazardous chemicals. Therefore, under the support of the department head and the guidance of the safety and environmental protection department, the emergency drill plan was designed.

Since I took over the management of chemical warehouse, I have been thinking about how to really strengthen the safety protection awareness of operators, so as to timely control and properly handle the sudden leakage of hazardous chemicals. Therefore, under the support of the department head and the guidance of the safety and environmental protection department, the emergency drill plan was designed.Simulated situation

At 13:20 on March 18, the warm spring breeze was caressing the earth. Without warning, No.2 warehouse of dangerous chemical warehouse was accidentally punctured and leaked due to the latex barrel. The latex is a white almost odorless fluid, which will pollute the water quality when dissolved with water, and the residue will pollute the environment. Therefore, during daily transportation, it needs to be transported in a single barrel. Before transportation, it is necessary to check whether the package is complete. During transportation, the speed should be gentle to avoid bumpy leakage.

Drill process

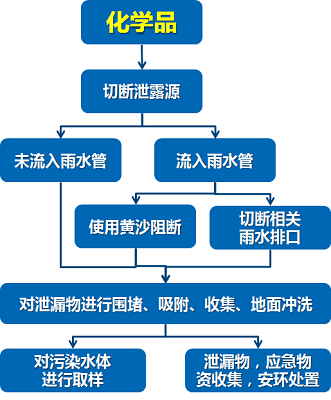

In this exercise, we simulate from four aspects:

Information notification: when forklift operator Liu discovers the leakage of hazardous chemicals, he immediately withdraws to the safe place and informs the supervisor and the communication group. The communication group informs the Department Director, the company's emergency communication center, safety and environment department, public service department and nearby support department of the name, property, location and other important information of the leaked materials.

Information notification: when forklift operator Liu discovers the leakage of hazardous chemicals, he immediately withdraws to the safe place and informs the supervisor and the communication group. The communication group informs the Department Director, the company's emergency communication center, safety and environment department, public service department and nearby support department of the name, property, location and other important information of the leaked materials.Emergency disposal: as the on-site commander of the drill, I assigned tasks according to the emergency plan. The staff of the fire control group used the materials in the emergency box to rescue the leakage of dangerous chemicals; The traffic control group conducts on-site partition and traffic control in the vicinity.

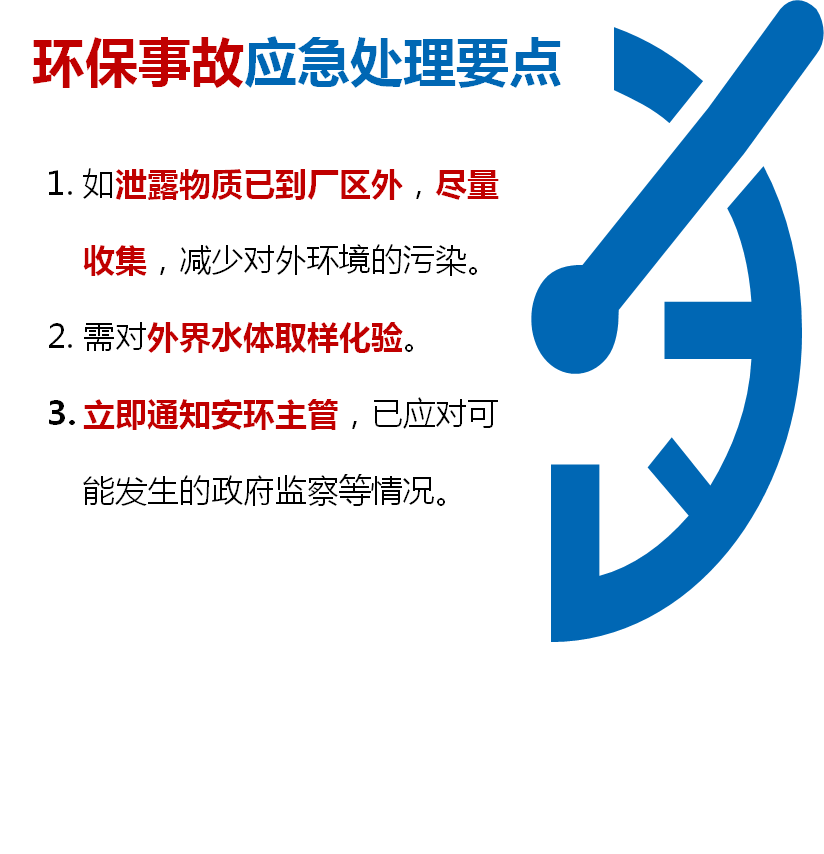

Sending samples for testing: the fire team will place the treated waste liquid and cloth in the collection bucket, and the treated surface water quality will be sampled and sent to the public sector for testing. The test results meet the environmental protection standards. All the drill personnel will withdraw from the site and gather at the assembly point.

Summary of the drill: after the drill, all the staff will watch the video of the drill together, and review the deficiencies in the process of the drill, the reasons for the leakage of hazardous chemicals, and the rectification plan. The front-line staff watched the drill video from the perspective of the third party manufacturer and discussed the experience warmly. Several experienced forklift workers also spoke frankly about the deficiencies and improvement suggestions they saw. Through this form, they comprehensively reviewed the implementation of SOP. The safety and Environment Manager Wang Wei also explained and guided you from the Perspective of safety.

Oriental industries (Suzhou) is located in Wuzhong chemical industry park, Suzhou. As a key fire fighting enterprise, we actively learn from the experience of self drilling and watching the accident videos of other units, so that every colleague can have the ability to deal with emergencies. From "safety wants me" to "I want safety", that is the significance of this drill. It is the promotion of front-line operators, department heads, safety and environmental protection departments, leaders at all levels of the company, as well as directors and colleagues at all levels, such as Cai Gaosheng, vice president of the company, Wu Moji, chief operating officer, etc., that has enhanced the safety awareness of Oriental Petrochemical (Taiwan) people. Safety is no small matter, everything needs to be done with all one's heart, take precautions, start from you and me!

#