11.2022 Cover Story

Focus on sustainable Far Eastern New Century Corporation to show its green strength

Far Eastern Magazine / Editorial Room

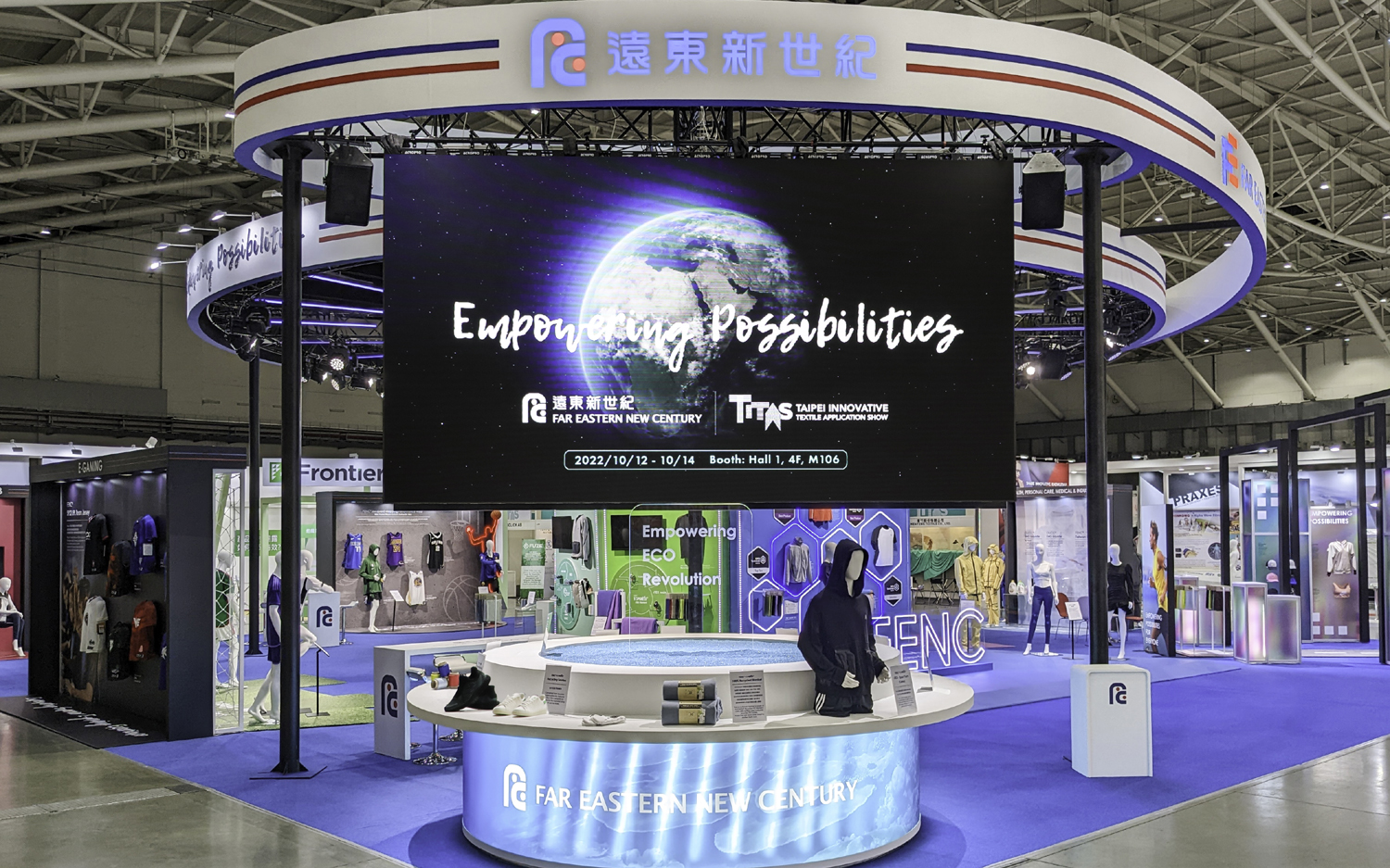

.jpg) Last year, in response to the epidemic situation, the "Taipei Innovative Textile Application Show, TITAS (Taipei Innovative Textile Application Show, TITAS)" was changed to an online exhibition. This year, it returned to the physical exhibition and made a grand debut in Taipei Nangang Exhibition Center 1 from October 12 to 14. Far Eastern New Century Corporation, which is the most popular company every year, will show the most advanced green fiber spinning technology and products this year. In response to the global trend of net zero carbon emissions, Far Eastern New Century Corporation this year, with sustainability and carbon reduction as the main axis, divided the center of the exhibition area into six special zones, including Spun Yarn, Filament, ISPO International Award, IDM x FEFC, Knitting&Dyeing and Research&Development, to highlight the one-stop production advantages and green research and development achievements. The exhibition area is surrounded by the theme of Everyday, Everywhere, Everyone and Sustainability, paired with the jerseys provided by Far Eastern New Center Corporation for important sports events such as the World Cup Football Match and the NBA, which symbolizes that the new environmental protection products of the Far Eastern Group are ubiquitous and integrated into the daily life of each people.

Last year, in response to the epidemic situation, the "Taipei Innovative Textile Application Show, TITAS (Taipei Innovative Textile Application Show, TITAS)" was changed to an online exhibition. This year, it returned to the physical exhibition and made a grand debut in Taipei Nangang Exhibition Center 1 from October 12 to 14. Far Eastern New Century Corporation, which is the most popular company every year, will show the most advanced green fiber spinning technology and products this year. In response to the global trend of net zero carbon emissions, Far Eastern New Century Corporation this year, with sustainability and carbon reduction as the main axis, divided the center of the exhibition area into six special zones, including Spun Yarn, Filament, ISPO International Award, IDM x FEFC, Knitting&Dyeing and Research&Development, to highlight the one-stop production advantages and green research and development achievements. The exhibition area is surrounded by the theme of Everyday, Everywhere, Everyone and Sustainability, paired with the jerseys provided by Far Eastern New Center Corporation for important sports events such as the World Cup Football Match and the NBA, which symbolizes that the new environmental protection products of the Far Eastern Group are ubiquitous and integrated into the daily life of each people. Cooperate with Uni President Group to expand the field of plastic and used clothing recycling and reproduction

Cooperate with Uni President Group to expand the field of plastic and used clothing recycling and reproductionFar Eastern New Century Corporation has been engaged in the recycling of PET bottles for more than 30 years. In the process, it has continuously improved the recycling and R&D technology, making waste PET bottles into a variety of fibers, including TOPGREEN ® The series is the most famous in the industry, and is widely used in clothing, sports shoes, bags and bags, as well as interior decoration materials of cars. Recently, it was announced that 7-ELEVEN and Tongyi Packaging will build an exclusive "recycled economy resource recycling machine" in the 7-ELEVEN store in the north district to recycle waste PET bottles, and then make high-quality recycled polyester granules through the exclusive technology of Far Eastern New Century Corporation for sorting, cleaning, decontamination and viscosity lifting, It is applied to environmental protection uniforms and other commodities in 7-ELEVEN stores to build a sustainable green and sustainable ecosystem.

In addition to PET bottles, used clothes are also one of the items that people often recycle. In fact, due to technical limitations, tens of millions of tons of used clothes can not be properly disposed of every year. In order not to waste people's love, Far Eastern New Century Corporation has been actively investing in R&D and improving the recycling technology of waste textiles since several years ago, making old clothes into new yarn, cloth and clothing. This year, the "visual fabric recycling polyester fiber" was upgraded to create a natural fried dough twist effect on the fabric without special dyeing. In the Spun Yarn area, Far Eastern New Century Corporation also showed that 100% polyester and 100% cotton textile wastes were transformed into 100% regenerated spun yarn by physical and mechanical method without adding any chemical products, and practical products such as clothes, backpacks, shoes and home decorations were produced. Another brand new "tannin recycled yarn" displayed in the special area is to create a fashionable and design sense of tannin style for waste fabrics.

Sea waste recycled fiber becomes the favorite of international sports events

Sea waste recycled fiber becomes the favorite of international sports eventsIn recent years, environmental awareness has risen, and the issue of marine waste plastics has attracted global attention. Many enterprises have held beach cleaning activities ®、 The marine environmental protection organization Parley for the Oceans cooperates with the project of "Marine Recycling Yarn" to transform marine waste plastics into fibers with high added value and then make them into sports shoes and clothing, effectively preventing the pollution of the ocean by more than 11000 tons of plastics. In the near future, we will further add color masterbatch to the spinning stage of marine recycled yarn to make colored yarn to replace the traditional fabric dyeing process, which can greatly reduce energy consumption and water consumption, block marine pollution, and reduce carbon dioxide emissions.

Far Eastern New Century Corporation has become one of the core suppliers of jersey materials for international sports events for a long time due to its high standard weaving technology, one-stop production and other characteristics, as well as its ability to develop green energy-saving fibers and quickly respond to the needs of brand customization. The training clothes of the multi national team for the 2020 Tokyo Olympic Games, the jerseys of the 2022 NBA final championships Golden State Warriors and the 2021 NBA final championships Milwaukee Bucks, which are hung high in this year's exhibition hall, are all made of fabrics provided by Far Eastern New Century Corporation. In the 2022 World Cup, which will be held in late November, teams from nine countries will compete in the jerseys made by Far Eastern New Century Corporation. Among them, seven countries, including Germany, Japan, Spain, Argentina, Mexico, Belgium and Wales, have been determined to enter the finals. In order to let the players work hard without worries, Far Eastern New Century Corporation has made great efforts in the jersey, not only using ocean recycled yarn, but also considering that the players must withstand various fierce collisions in the course of the game. It is the first to apply the powerful anti explosive weaving technology to the jersey. The clothing itself has undergone multi-directional composite stress test and strict blasting test, plus hundreds of practical applications by players, and according to the ductility of different parts of the human body and the required strength, the most appropriate and independent fabric structure has been designed to make the jersey more integrated with the players and become the most powerful backing for the players.

Source waste reduction technology won international awards

Source waste reduction technology won international awardsAlthough it is important to reduce existing waste, Far Eastern New Century Corporation knows that to realize the dream of sustainability, waste must still be reduced from the source. In view of the high water consumption and high pollution of fibers in the dyeing process, which has always been a major issue in the textile industry, Far Eastern Fibertech, a subsidiary of Far Eastern New Century Corporation, specially developed "Nylon 6,6 Stock Solution Dyed Fibers", which can be colored without the need for later dyeing process, greatly reducing the consumption of chemical dyes, auxiliaries and water resources, and omitting the treatment of dyeing wastewater, so as to achieve the effect of energy conservation and carbon reduction.

On the other hand, air pollution is also a headache for environmental protection. However, Far Eastern New Century Corporation should not only reduce waste, but also "turn waste into treasure". In July last year, the "Carbon Capture and Utilization (CCU)" technology was successfully applied to produce the world's first low carbon polyester fiber garment made from the waste gas of the steelmaking plant. This year, it officially entered the mass production stage. In this exhibition hall, the finished products and relevant process drawings are specially displayed, so that visitors can better understand their principles. At the same time, Far Eastern New Century Corporation also combined this fiber with the nylon 6,6 stock solution dyeing technology of Far Eastern Fibertech to develop a new FENC ® TOPGREEN ® BIO3 environment-friendly fabric, which not only stands out from more than 200 material suppliers in the world, won the highest honor "Best Product" (the best environment-friendly product award) of German ISPO TEXTRENDS (International Textile Trend Award), but also won the "2022 Sustainable Innovation Award" awarded by the International Textile Manufacturing Federation (ITMF).

The joy of winning the prize has further strengthened the pace of the green transformation of Far Eastern New Century Corporation. In addition to further applying the waste gas recycling and recycling polyester technology to industrial fiber materials with higher difficulty, and developing renewable polyester environment-friendly fibers that are completely made of waste plastic bottles for re granulation and spinning, after weaving into tire cord fabric, they are supplied to German Mark Tire Company to produce environment-friendly tires, In addition, we have launched cooperation plans with a number of vehicle material companies such as airbags and safety belts. In view of the rapid growth of electric vehicles, Far Eastern Group has also cooperated with international famous electric vehicle manufacturers such as TESLA to produce polyester curtain airbag since 2021 to achieve the environmental goal of lightweight carbon reduction. At present, the sales volume has grown steadily.

New Solution of Biodegradation Technology Recycled Economy

New Solution of Biodegradation Technology Recycled EconomyOver the past few years, COVID-19 has ravaged the world. Although wearing masks can effectively prevent the spread of the epidemic, more than 4 billion discarded masks are produced every day around the world. In the case of the epidemic, these "toxic wastes" will continue to be the "necessary evil" in the post epidemic era.

Far Eastern New Century Corporation actively fulfilled its social responsibility. At the beginning of the epidemic, it supplied up to 600 tons of fibers for masks every month, and developed innovative fibers to reduce the use of melt blown nonwovens. In order to help the world solve the problem of discarded masks, we will develop non-woven fiber raw materials for biological and biodegradable masks in 2021. In addition to having the same hydrophilic, skin friendly, soft and other qualities as petrochemical fibers, they can also be naturally decomposed in an appropriate burial environment, and can be used in various non-woven products such as masks, diapers, wet paper towels, sanitary cotton, facial mask, etc. Among them, biological and biodegradable materials can also be combined with plastic recycled from PET bottles or marine recycling to make fibers, so as to achieve the goal of recycled economy.

The pursuit of sustainability is not only the goal of Far Eastern New Century Corporation, but also the common direction of enterprises under the Far Eastern Group. In the "Sustainable Zone", in addition to displaying various green products of Far Eastern New Century Corporation, OUCC developed by Oriental Union Chemical Corporation ® TopGreen ® Surfactant series products, including zinc oxide antibacterial lotion (OUCC ® ZnO liquid and OUCC ® Fabric shield), which are functional ethylene oxide derivatives, have been adopted by many famous detergent brands, and made into detergent products, which can be purchased by a large number of vendors. In the future, Oriental Union Chemical Corporation also plans to expand OUCC ® TopGreen ® The application of Surfactant series products combines ethylene oxide derivatives with the new recycled polyester of Far Eastern Group to produce environment-friendly surfactants, providing more choices for green consumption.

In addition, "TopGreen", a special gift jointly made by Far Eastern New Century Corporation and Far Eastern Group Far Eastern Apparel ® Environmental protection and sustainable warmth blanket "is also a highlight of this year's TITAS exhibition. The blankets are made of recycled PET bottles, and have the spirit of both bedding texture and environmental sustainability. They have also passed the GRS, SCS, Taiwan environmental protection seal, and Oeko Tex ® 100 ecological textile standard, the first class product level... and other certifications have been widely praised by the media and investors. Far Eastern Group Far Eastern Apparel also makes blankets into practical sizes for sale, so that more consumers can actually feel the ingenuity and warmth of environmental protection.

In order to achieve the goal of Net Zero in 2050, Far Eastern New Century Corporation will continue to give play to the advantages of vertical integration and cross field technical cooperation, start from various links such as process, fuel, energy, raw materials, transportation, and through new technologies of land, sea and air waste recycling and reproduction, to create a new generation of green products and usher in a sustainable future.

#