01.2025 Office Talk

From the perspective of the factory, the transformation of Oriental Petrochemical (Taiwan)

Ya Tung Ready Mixed Concrete Corporation Yongkang Factory / Lin Hongda

Ya Tung Ready Mixed Concrete Corporation has been deeply rooted in Taiwan for over 20 years. As an employee who has grown from a young man to the age of destiny, I deeply feel the company's transformation in technological innovation and differentiated product performance improvement in recent years; Recalling the period of expanding territory in the past, there was vicious competition among peers, and the sales price of concrete was only guaranteed to exceed the marginal contribution, let alone gross profit; But with market changes, improvement in self quality technology, stability of concrete mix, and excellent customer service, we have ultimately gained recognition from our customers. Now, we focus on intelligent AI and sustainability development, successfully shaping our brand image, enhancing market competitiveness, and creating operating gross profit.

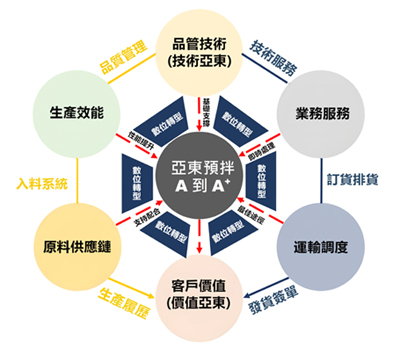

Ya Tung Ready Mixed Concrete Corporation has been deeply rooted in Taiwan for over 20 years. As an employee who has grown from a young man to the age of destiny, I deeply feel the company's transformation in technological innovation and differentiated product performance improvement in recent years; Recalling the period of expanding territory in the past, there was vicious competition among peers, and the sales price of concrete was only guaranteed to exceed the marginal contribution, let alone gross profit; But with market changes, improvement in self quality technology, stability of concrete mix, and excellent customer service, we have ultimately gained recognition from our customers. Now, we focus on intelligent AI and sustainability development, successfully shaping our brand image, enhancing market competitiveness, and creating operating gross profit.The series of changes carried out by Ya Tung Ready Mixed Concrete Corporation have not only gained recognition and appreciation from customers for product quality, but also created higher brand value for the company, promoting its A-level position in the industry. This journey has been both a challenge and an opportunity. In summary, the following three aspects have contributed to the development of Oriental Petrochemical (Taiwan) today.

1、 Management aspect

In the early days, Ya Tung Ready Mixed Concrete Corporation imported ISO9001 quality management system certification, and later combined it with the High Quality Concrete Verification System (GRMC) and CNS standards. Through controlling raw material sources, updating process equipment, optimizing mix proportions and quality technology, close interaction with customer service, and promoting standard deviation and coefficient of variation control that meets the American national standard ACI214 Ultimate Quality (Excellent), it laid the foundation for the Oriental Petrochemical (Taiwan) brand. In response to the 2050 net zero carbon emission policy, Oriental Petrochemical (Taiwan) has successively obtained ISO45001 (Occupational Safety and Health Management System), ISO14001 (Environmental Management System), ISO50001 (Energy Management System), and ISO27001 (Information Security Management System) certifications. With continuous guidance and improvement from internal and external audits, the factory's operating model has established rules and regulations to follow, and work safety protection has become more sound; The establishment of 5S management method (reorganize SEIRI, rectify SEITON, clean SEISO, clean SEIKETSU, cultivate SHITSUKE) has beautified the factory environment; The implementation of energy conservation and carbon reduction has accelerated the promotion and application of the new generation of PLC concrete... These measures have continuously improved the factory management. The headquarters and various districts have combined Power BI Big Data with a nationwide database and established an EIS operation information management system to constantly monitor the operation status of each factory, provide decision-making support, and implement management and monitoring.

In the early days, Ya Tung Ready Mixed Concrete Corporation imported ISO9001 quality management system certification, and later combined it with the High Quality Concrete Verification System (GRMC) and CNS standards. Through controlling raw material sources, updating process equipment, optimizing mix proportions and quality technology, close interaction with customer service, and promoting standard deviation and coefficient of variation control that meets the American national standard ACI214 Ultimate Quality (Excellent), it laid the foundation for the Oriental Petrochemical (Taiwan) brand. In response to the 2050 net zero carbon emission policy, Oriental Petrochemical (Taiwan) has successively obtained ISO45001 (Occupational Safety and Health Management System), ISO14001 (Environmental Management System), ISO50001 (Energy Management System), and ISO27001 (Information Security Management System) certifications. With continuous guidance and improvement from internal and external audits, the factory's operating model has established rules and regulations to follow, and work safety protection has become more sound; The establishment of 5S management method (reorganize SEIRI, rectify SEITON, clean SEISO, clean SEIKETSU, cultivate SHITSUKE) has beautified the factory environment; The implementation of energy conservation and carbon reduction has accelerated the promotion and application of the new generation of PLC concrete... These measures have continuously improved the factory management. The headquarters and various districts have combined Power BI Big Data with a nationwide database and established an EIS operation information management system to constantly monitor the operation status of each factory, provide decision-making support, and implement management and monitoring.2、 Business aspect

Traditional business development involves obtaining orders through networking, socializing, and price competition. However, with the digital transformation of Oriental Petrochemical (Taiwan), customer marketing in the new era has gradually shifted towards providing two-way benefits of customer added value, which can be roughly divided into three categories:

(1) Radial development of new customers: Through real estate associations or construction management associations, large-scale concrete product seminars are held, inviting construction companies, developers, builders, etc. to introduce technological innovation and research and development results in a point to many radial manner, attracting customer resonance and ultimately paying the bill.

(2) Digital marketing: using digital tools and cloud database management to achieve marketing goals, such as establishing a customer relationship management system (CRM) to effectively manage, analyze, and improve customer relationships and marketing methods; Marketing Oriental Petrochemical (Taiwan) product quality and technology research and development information through SEM (search engine marketing) and promotion on Facebook, Yutube, Instagram, etc; Upload the complete product brief to the cloud database for easy access by speakers or business personnel at any time.

(3) Differentiated product services: promoting HFC HPRC、SCC、 High end differentiated products such as permeable concrete and plain concrete, with leading technology and product stability in the industry, have become the preferred pre mix factory for customers.

3、 Quality aspect

Ya Tung Ready Mixed Concrete Corporation has transformed from traditional manual labor to digital technology, achieving great success in concrete quality management and product traceability. Through the quality management app and IoT digital analysis technology, it can not only manage raw material and product data in real time, but also ensure the accuracy and stability of concrete mix proportions.

In the past, the production process of concrete was often delayed due to spatial and temporal differences in raw material inspection and product quality prediction, and experimental data could only rely on paper records, which could not provide real-time feedback and analysis; In 2023, Ya Tung Ready Mixed Concrete Corporation collaborated with Far EasTone Telecommunication to successfully develop the Oriental Petrochemical (Taiwan) Quality Management System App, which includes functions such as raw material sampling, testing methods, data analysis, and influencing factor database. This enables quality control personnel to design the optimal ratio based on the characteristics and feeding sequence of raw materials, improve the compressive strength and stability of products, and collect and analyze quality information of raw materials in real time, including entry time, quality, and supplier information, in order to quickly identify abnormal situations and take immediate measures to reduce product quality risks; At the same time, company executives can easily grasp the sales situation and production and delivery status of each factory, further improving management efficiency and competitiveness. In addition, each batch of products is assigned a unique barcode identification number, which links the product's factory information with client information, enabling full traceability of concrete products and providing greater protection for customers.

In the process of continuous growth and progress, Ya Tung Ready Mixed Concrete Corporation has the hard work and dedication of its predecessors. Now, under the leadership of professional manager President Kim Chong ren, it is actively promoting the transformation of its business system in the next 5 to 10 years, especially in the layout of intelligent AI and digitization, laying a solid foundation for the new generation of ready mixed concrete manufacturing industry. We are well aware that while profitability is an important goal for businesses, ESG (Environmental, Social, and Governance) is the fundamental principle of sustainability development. Therefore, we have compiled and published our first pre mixed industry ESG report in 2023, believing that the concepts of "Today is the best, tomorrow is better" and "Better than Best" will lead us forward and continue to grow rapidly. I am proud of Far Eastern and even more proud to be from Oriental Petrochemical (Taiwan)!

#