03.2020 Cover Story

Asia Cement Corporation's diversified investment and operation to build a world-class cement kingdom

Far Eastern Magazine / Editorial Room

Asia Cement Corporation reaped a harvest in business operation in 2019, with a significant growth in both the mainland market and the reinvestment business. In terms of cement production, Taiwan's annual output was about 5 million tons, and output in the mainland was 40 million tons, and with the cement of Sunnsy Group, Asia Cement Corporation has successfully become an enterprise with 100 million tons of cement. For the sustainable operation of the industry, Asia Cement Corporation continues to innovate and upgrade, promoting cement and downstream concrete industry with green development and digital transformation, to build a world-class cement kingdom.

Recycled economy is popular, cement industry finds the way for waste treatment

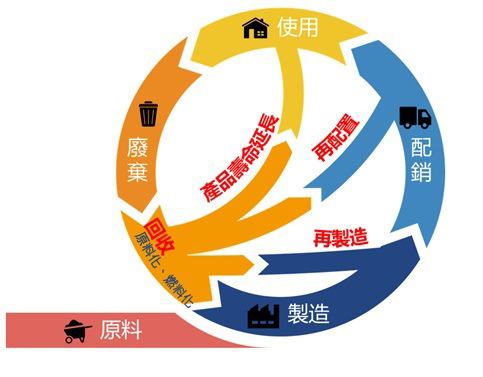

"Linear economy" represents the process from raw material production to waste. It is not environmentally friendly, but the main consumption mode of people in the past. The opposite concept of "linear economy" is "recycled economy". With the rising awareness of environmental protection, consumers are gradually implementing environmentally friendly behaviors in their lives. For example, when things are broken, they find parts to repair, idle items are transferred to other people for use, and tires are ground to make remanufactured tires. Different industries pay more and more attention to their cooperative relationship and close connection. What industry A can't use happens to be raw materials or fuels for Industry B. Anything that can extend product life, reallocate or remanufacture assets is the concept of recycled economy.

Asia Cement Corporation Zhang Zhipeng General Plant Manager (senior executive vice president) "With the revision of China's waste disposal law in 2017, waste producers should take the responsibility of final disposal. The more careful we have to deal with waste, the lower the capacity of waste incinerators, the time-consuming overhaul, and the saturation of the landfill space, it is not easy to set up new sites. Even if the incinerators, they can only reduce the waste to 1 / 7, the final disposal or surface treatment For some refractory wastes, it still depends on the cement industry, which makes the role of cement plant in recycled economy more popular. "Not only that, the cement plant's assistance in waste disposal can reduce the use of natural raw materials and fuels, which can help to reduce costs. However, Zhang General Plant Manager (senior executive vice president) stressed that" to fulfill social responsibility, reduce social costs and create social value of cement industry is the introduction of recycled economy by Asia Cement Corporation The most important factor. "

Zhang Zhipeng, General Plant Manager (Senior Executive Vice President) said "With the revision of China's waste disposal law in 2017, waste producers should take the responsibility of final disposal. So we have to deal with waste more carefully. And the waste incinerators almost are out of run, the capacity is decreasing, the overhaul is time-consuming. Due to the saturation of the landfill space, it is not easy to set up new sites. Even if the incinerators, they can only reduce the waste to 1 / 7, and it still depends on the cement industry in dealing with the refractory wastes, which makes the role of cement plant in recycled economy more popular." Not only that, the cement plant's assistance in waste disposal can reduce the use of natural raw materials and fuels, which can help to reduce costs. However, General Plant Manager, Zhang Zhipeng, stressed that" to fulfill social responsibility, reduce social costs and create social value of cement industry are the most important factor for Asia Cement Corporation to introduce recycled economy. "

In order to achieve triple-win situation for waste producers, central and local authorities, Asia Cement Corporation actively communicates with all parties in the process of promoting recycled economy, prioritizes the disposal of waste entrusted by the government and difficult to be solved by local industries, and participates in various recycled economy seminars, it is dedicated to integrating professional technology, assisting the government in formulating laws and regulations, and creating greater influence. General Plant Manager, Zhang Zhipeng, took the mixed burning ash as an example. "After discussion with the environmental protection unit and legislator, Asia Cement Corporation formulated relevant regulations to send the mixed burning ash to the cement plant as raw materials, so as to avoid secondary pollution caused by the mixed burning ash."

In addition, General Plant Manager, Zhang Zhipeng, also mentioned "water purification sludge". In Taipei, 50000 tons of water purification sludge is handled by Asia Cement Corporation every year, which is not only highly praised, but also a task we are very proud of.” Asia Cement Corporation has disposed 150000 tons of waste in 2019, and it is estimated that it will increase to 450000 tons in 2020, and move towards the goal of 800000 tons in 2024.

Green concrete moves towards intelligent and high-end market

The ready mixed concrete, located in the downstream of the cement industry, is the most important and the largest material in the construction. It is not only accompanied by the development of human civilization, but also an indispensable industry in the future. Its products are also progressing with the technology. Chen Zhengping, President of Ya Tung ready mixed concrete corporation, pointed out that "the concrete has moved towards the direction of high-performance concrete, such as high flow, high impermeability, ultra-high strength, etc. it is worth mentioning that the steel fiber concrete of all the tunnels in the section B3 of repair of Suhua Highway, which just opened to traffic, were provided by Ya Tung ready mixed concrete corporation, which is a big affirmation of our company's high quality concrete. "In the future, in addition to the development of high-end concrete products, permeable, lightweight concrete and other special products will be an important trend in the overall industry.

For this reason, Ya Tung Ready Mixed Concrete Corporation plans to focus on three aspects of operation and development, the first is green production, "the first is the reuse of waste resources. According to President, Chen Zhengping " Ya Tung Ready Mixed Concrete Corporation makes full use of industrial by-products such as fly ash and furnace stone powder, and currently accounts for up to 40% of cementitious materials.". This "green concrete" practice has applied to the Department of Internal Affairs for the green building materials certificate. In order to reduce air pollution and carbon emissions, Ya Tung Ready Mixed Concrete Corporation has successively purchased 75 environmental protection phase V ready mixed concrete vehicles in 2019, replacing the environmental protection phase II ready mixed vehicles. Each vehicle can reduce air pollution and carbon emissions by about 20% and 32%. In addition, Ya Tung Ready Mixed Concrete Corporation is also committed to improving the reuse of recycled water, adding desilter equipment to recycle the sewage from vehicle drum cleaning. The use of recycled water in each plant has increased from 20% to 40%, and the reuse rate has doubled.

In addition to green production, Ya Tung Ready-Mixed Concrete Corporation also keeps up with the trend of intelligent operation and management. President, Chen Zhengping said frankly, "industry 4.0 and AI are the future trends. At present, we are building an APP for quality control, business marketing and transportation management, hoping to grasp the status of production, transportation and marketing in real time through the APP."

With intelligent management, Ya Tung Ready-Mixed Concrete Corporation also actively develops high-end products and accelerates industrial transformation. Taking sound insulation concrete as an example, the Department of Internal Affairs announced the law of floor sound insulation that since July this year, the number of floor decibels must be reduced by 17-20 decibels. Therefore, Ya Tung Ready-Mixed Concrete Corporation has started to develop relevant products and expect to seize the sound insulation floor market. The other is the research and development of lightweight concrete, which is 20% lighter than ordinary concrete and can be used in bridges, steel floors and compartments. As for pervious concrete, it is a sustainable green development, President, Chen Zhengping noted: "this product, especially in the south area, has higher sales. It can not only store rainwater, but also reduce the atmospheric temperature. At present, it is mostly used in sidewalks, squares and parking lot floors. It is estimated that it will be a powerful tool to implement the" sponge city ". It is definitely a good news for Taiwan, which is plagued by water shortage. On the other hand, at the raw material end, Ya Tung Ready-Mixed Concrete Corporation cooperates with Oriental Union Chemical Corporation to develop concrete admixtures, which can not only give full play to the synergy of the group, but also produce more customized products and create customer value.

President Chen Zhengping expects Ya Tung Ready-Mixed Concrete Corporation to become the leader of high-end concrete products, develop high-end products and raw materials gradually with green production concept and intelligent management mode, and move forward steadily.

Due to the mature and saturated market, Taiwan's cement industry has more urgent demand for industrial breakthrough and transformation. Asia Cement Corporation continues to expand its operating tentacles on the basis of cement, in addition to innovating value by recycling economy, we should actively expand the downstream channels and capture the concrete industry; the companies in the mainland continues to pursue growth by means of mergers and acquisitions and alliances; the electric power industry that has been reinvested, including natural gas power plants and green energy offshore wind power, is a great help for Taiwan to overcome the power shortage crisis. Among them, the benefit of Chiahui phase I is stable, and after the completion of phase II, the power generation capacity will be multiplied. In addition to the electric power business, Yuan Long Stainless Steel Corporation has also made great efforts to develop the international market and expand its operation scale; in addition to the original land transportation, Fu Ming transport has further stepped into the logistics business to expand the new business territory. Through diversified investment and operation, Asia Cement Corporation not only creates a new wave of growth momentum, but also makes the old brand and world-class cement Kingdom full of innovation and vitality and keeps sustainable development.