07.2024 Cover Story

Far Eastern General Construction Inc.'s commitment to sustainability through low-carbon construction methods

Far Eastern Magazine / Editorial Room

Green buildings have become a trend in the new era, but the scale of construction projects is vast, and many materials and construction methods have been used for years. How can steel and cement become "green"? This cover story takes you on a visit to the construction site of Far Eastern General Construction Inc. to see how they demonstrate their commitment and dedication to energy conservation and carbon reduction in projects such as tourist hotels, residential buildings, and even public works.

Green buildings have become a trend in the new era, but the scale of construction projects is vast, and many materials and construction methods have been used for years. How can steel and cement become "green"? This cover story takes you on a visit to the construction site of Far Eastern General Construction Inc. to see how they demonstrate their commitment and dedication to energy conservation and carbon reduction in projects such as tourist hotels, residential buildings, and even public works.Taoyuan Aviation City plans to leverage recycled economy benefits

As a gateway city to Taiwan, Taoyuan International Airport is located in an advantageous international logistics location and is also a fortress connecting cities in the Asia Pacific region. In response to the demand for the construction of the third runway, the competent authority has planned the Taoyuan Aviation City Plan, which aims to readjust the land use around the airport and enhance competitiveness and international development. Far Eastern General Construction Inc. is responsible for undertaking the D1 sub contracting project, designing various roads, residential areas, production zones, cross highway landscape bridges, Pitang Park and green belts, commercial areas, etc. in the area, and working with ZTE Engineering Consultant to deeply discuss recycled economy materials and energy-saving and carbon reduction designs within the green belt, striving to create a "green, sustainable and healthy city".

The benefits of combining recycled economy with engineering include not only prolonging the lifecycle of resources, but also reducing waste generation, establishing a sustainable and renewable environment where resources can be restored. Therefore, Far Eastern General Construction Inc. has invited Central Plains University to participate in the research on "Reusing Incinerator Bottom Residue for Soil Stability". The relevant research and development results will be applied to subsequent construction, and in accordance with government regulations, recycled economy materials with high production in Taoyuan City will be used for road engineering paving and controlled low strength backfill materials.

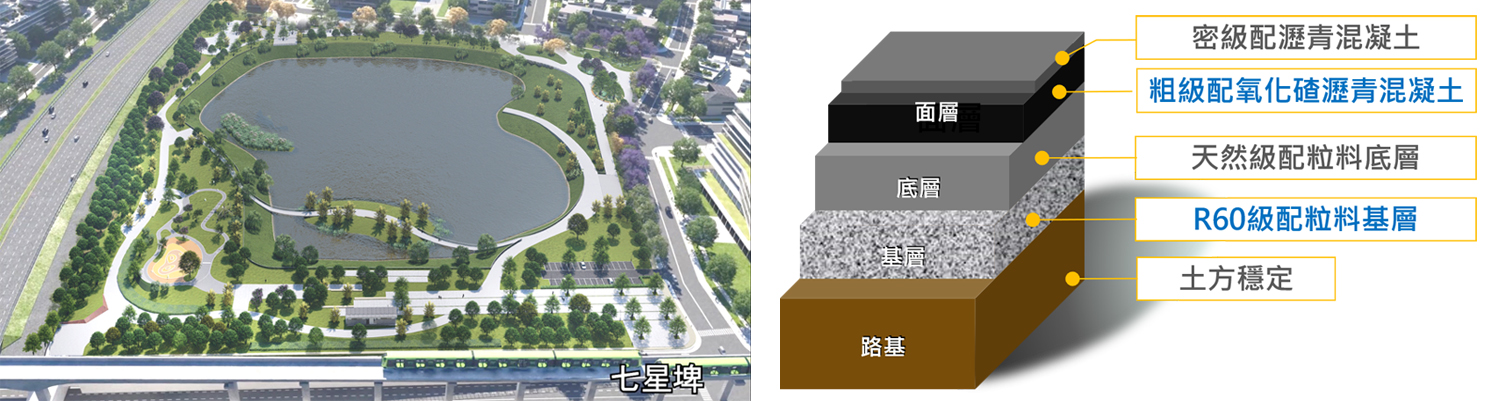

For example, the byproduct generated by the arc steelmaking process, "arc steelmaking oxide slag," has always been recognized as waste. However, in fact, its hard texture can improve the bearing capacity and wear resistance of the pavement. When added to asphalt concrete, it can replace some natural graded particles. Far Eastern General Construction Inc. is planning to use oxidized slag asphalt concrete in the road surface layer, successfully reusing slag resources.

In addition, the leftover material after the removal of asphalt concrete pavement can also be used for road base grading after treatment to replace natural grading (with an upper limit of 60%). Therefore, in this project, Far Eastern General Construction Inc. specifically removed asphalt concrete from existing roads in the redevelopment area, mixed it in a compliant proportion, and became "graded granular base (mixed with recycled materials)", replacing natural graded granular materials for secondary and neighboring road base grading.

At present, there are a total of 24 incineration plants in Taiwan, processing nearly 20000 tons of garbage every day, producing a large amount of bottom slag and fly ash, which instead become new waste. In fact, the physical properties of "incinerated recycled aggregates" are similar to natural sand and can be used as engineering materials instead of natural aggregates. Environmental Protection Administration also actively promotes the application of incinerated bottom slag recycled aggregates in road base layers, controlled low strength backfill materials, bricks, cement raw materials, and landfill cover soil. Far Eastern General Construction Inc. responds to the recycled economy concept by mixing incinerated recycled aggregates with existing wet soil for use in park trails, squares, parking lots, and other locations. Additionally, it plans to use incinerated recycled aggregates as a controlled low strength backfill material, suitable for trench backfilling or other excavation backfilling projects except for water pipelines. In addition, some paving bricks in parks, squares, sidewalks, and other areas also use environmentally friendly concrete floor tiles with added incinerated recycled aggregates, which is estimated to help dispose of 504 tons of incinerated recycled aggregates.

At present, there are a total of 24 incineration plants in Taiwan, processing nearly 20000 tons of garbage every day, producing a large amount of bottom slag and fly ash, which instead become new waste. In fact, the physical properties of "incinerated recycled aggregates" are similar to natural sand and can be used as engineering materials instead of natural aggregates. Environmental Protection Administration also actively promotes the application of incinerated bottom slag recycled aggregates in road base layers, controlled low strength backfill materials, bricks, cement raw materials, and landfill cover soil. Far Eastern General Construction Inc. responds to the recycled economy concept by mixing incinerated recycled aggregates with existing wet soil for use in park trails, squares, parking lots, and other locations. Additionally, it plans to use incinerated recycled aggregates as a controlled low strength backfill material, suitable for trench backfilling or other excavation backfilling projects except for water pipelines. In addition, some paving bricks in parks, squares, sidewalks, and other areas also use environmentally friendly concrete floor tiles with added incinerated recycled aggregates, which is estimated to help dispose of 504 tons of incinerated recycled aggregates.Creating a sound green environment is the mission of Far Eastern General Construction Inc. The team uses the Low Impact Development Method (LID) to set up detention ponds, planting ditches, planting troughs, and rainwater storage facilities in park green spaces, breaking away from the traditional single detention pond drainage design, maintaining water quality and quantity from the source, effectively responding to changes in rainfall, and improving the water retention capacity of the base. The two existing ponds in the area are also maintained using LID construction method, while retaining the surrounding natural slope surfaces; In addition to the Pitang detention pool, the top of the detention park embankment, along the Puxin River, the green space on the highway, and the green belt on the road create artificial depressions, purified grass ditches, permeable pipes, and rainwater gardens with natural slopes on the surface, constructing green gardens that can collect rainwater and delay discharge. This not only reduces surface runoff pollution, but also has benefits such as water source conservation and rainwater recycling and reuse.

Far Eastern Group Jiaoxi Resort Hotel Energy Conservation and Carbon Reduction in All Directions

Global climate change is becoming increasingly severe, and the construction industry is one of the main sources of energy consumption and carbon emissions. Implementing energy-saving and carbon reduction measures is particularly important. In addition to reducing energy consumption, it can also reduce the execution cost of construction projects, improve project quality, and thereby extend the service life and sustainable development capacity of buildings. The under construction Far Eastern Group Reef Resort is one of the representative energy-saving building projects of Far Eastern General Construction Inc. in the field of tourist hotels.

As is well known, a building often takes several years and goes through multiple processes from conception to completion, and the demand for energy conservation and carbon reduction further tests the meticulous density of engineering planning and the professionalism of the team. The engineering plan of Far Eastern General Construction Inc. introduces low-carbon measures from three aspects. Firstly, the roof of the building is made of pre cast panels and high-efficiency insulation materials made of Japanese tiles, combined with energy-saving windows and doors, to improve the insulation effect of the building and reduce indoor and outdoor heat conduction; Secondly, design a permeable pavement and a water pump in the lower layer of the walkway to collect rainwater, which can be used to irrigate plants, clean the walkway, or serve as a small fire water storage tank. In addition to achieving water resource recycling, it can also maintain soil stability, thereby increasing the permeability and breathability of the building's surroundings; In addition, in the energy supply sector, renewable energy such as solar and wind energy are used, and intelligent building control systems are used to automatically regulate the indoor environment and improve energy utilization efficiency.

.jpg) At the construction site, multiple operations are often carried out synchronously. Far Eastern General Construction Inc. strives to minimize the impact on the environment during the process, such as using fully enclosed dust nets during structural construction; When handling materials or construction waste that are prone to dust, cover and sprinkle water to reduce dust flying; Strengthen the classification, recycling, storage, and reuse of construction waste, and set up special pipelines or use elevators to transport waste and garbage from high-rise buildings; The remaining construction soil and stone generated from the demolition of buildings, such as gravel and earthwork, will be used to fill the existing foundation and pave roads.

At the construction site, multiple operations are often carried out synchronously. Far Eastern General Construction Inc. strives to minimize the impact on the environment during the process, such as using fully enclosed dust nets during structural construction; When handling materials or construction waste that are prone to dust, cover and sprinkle water to reduce dust flying; Strengthen the classification, recycling, storage, and reuse of construction waste, and set up special pipelines or use elevators to transport waste and garbage from high-rise buildings; The remaining construction soil and stone generated from the demolition of buildings, such as gravel and earthwork, will be used to fill the existing foundation and pave roads.Not only that, Far Eastern General Construction Inc. also utilizes pre assembly or pre casting technology to reduce dust and energy consumption on the construction site. In addition, for multi-layered and regular guest room buildings, reusable template systems and modular tools are used, and non reserved trees in the work area are sawn into shavings, which are fermented and decomposed into fertilizer on site to nourish the soil or processed into fuel rods as biofuels. Given the importance of green energy transportation to the environment, Far Eastern General Construction Inc.'s construction machinery and transportation vehicles have also obtained the Environmental Protection Administration's self management and excellent level certification. More importantly, all energy-saving and carbon reduction measures at the forefront of the project are monitored through monitoring systems and electronic recording instruments, recording the effectiveness of the implementation and storing it in a database.

Far Eastern Construction Forest Tpark Park Park Environmental Protection Smart New Building

The Taipei Far Eastern Group Communication Park (Tpark) has recently become one of the leading smart technology parks in northern Taiwan due to the entry of multiple internationally renowned technology giants and Google R&D headquarters. Among them, the newly built Far Eastern Construction project, Eco Park A and B, located in a corner of the park and adjacent to the MRT Far Eastern Memorial Hospital station, is a world-class building that combines advanced technologies such as aesthetics, intelligence, environmental protection, green energy, seismic isolation, and prefabricated construction. The design was initially aimed at silver grade green buildings and was constructed in two phases. The Eco Park B (hereinafter referred to as EPKB), which was first launched, is currently almost sold out. The upcoming Eco Park A (hereinafter referred to as EPKA) will also follow EPKB's strict selection of building materials, landscapes, and construction methods, and follow construction process standards to comply with dozens of environmental protection, energy conservation, and carbon reduction measures and material regulations such as soil depth, planting tree species, and energy efficiency, creating a model for silver grade green buildings.

The Taipei Far Eastern Group Communication Park (Tpark) has recently become one of the leading smart technology parks in northern Taiwan due to the entry of multiple internationally renowned technology giants and Google R&D headquarters. Among them, the newly built Far Eastern Construction project, Eco Park A and B, located in a corner of the park and adjacent to the MRT Far Eastern Memorial Hospital station, is a world-class building that combines advanced technologies such as aesthetics, intelligence, environmental protection, green energy, seismic isolation, and prefabricated construction. The design was initially aimed at silver grade green buildings and was constructed in two phases. The Eco Park B (hereinafter referred to as EPKB), which was first launched, is currently almost sold out. The upcoming Eco Park A (hereinafter referred to as EPKA) will also follow EPKB's strict selection of building materials, landscapes, and construction methods, and follow construction process standards to comply with dozens of environmental protection, energy conservation, and carbon reduction measures and material regulations such as soil depth, planting tree species, and energy efficiency, creating a model for silver grade green buildings.The fundamental challenge in building high-quality green buildings lies in overcoming technological limitations. Far Eastern General Construction Inc. collaborates with Japanese company Zhonglu Construction to introduce the latest generation of "double lotus root pre casting method" from Japan. The components are pre cast in the factory and then sent to the construction site for assembly and joint, achieving the goal of completing one floor in seven days and creating a fast, accurate, and high-quality new Taiwanese construction process. During the construction process, not only has the output significantly decreased to less than one-third of traditional construction methods, but construction waste has also been reduced to one tenth of the previous level, resulting in remarkable energy-saving and carbon reduction effects.

In addition, to reduce the demand for human labor during the construction process, Far Eastern General Construction Inc. specifically refers to the use of pre casting methods in China and Japan, and adopts a "self climbing construction scaffolding". After the unit is assembled on site, personnel move it to the construction floor with a tower crane for fixation, and use an electric chain system to climb, reducing the burden of manpower and avoiding energy consumption and carbon emissions caused by frame manufacturing and disassembly. At the same time, the team also abandoned the traditional external wall tiling method and switched to environmentally friendly and healthy coatings. On the one hand, it saves materials for tiles and mud, promotes energy conservation and carbon reduction, and on the other hand, it can also avoid the risk of tiles falling and injuring people.

In addition to improving traditional construction methods, the team has also developed a new cement material ratio to make concrete, which is applied to Far Eastern Construction Forest (Eco Park A, B). Due to the inclusion of Bu Zuo Lan material, it can improve the density and durability of concrete and reduce carbon emissions by 20-36%. Of course, the management and maintenance of residents after moving in also need to be properly planned. The coverage rate of Far Eastern Construction Forest (Eco Park A, B) is far below the legal standards, which can not only regulate the climate, but also retain a large amount of open space in the dense steel jungle of the metropolitan area. In response to the trend of green energy, the proportion of electric vehicle spaces in Eco Park A has been increased to 50%, allowing residents to enjoy a low-carbon and comfortable life.

In the Taoyuan Aviation City project, Far Eastern General Construction Inc. aims to reuse construction waste materials to achieve a recycled economy, and tailor a green, sustainable, and healthy city based on regional characteristics; When implementing the Far Eastern Group Jiaoxi Resort Hotel project, low-carbon measures were taken in all aspects such as design thinking, materials, equipment, etc. to improve the reuse rate of resources and create environmentally friendly green leisure spaces; Faced with the construction of Far Eastern Construction Forest (Eco Park A and B), advanced technology and construction methods were introduced to accompany the growth of Taipei Far Eastern Group Communication Park (Tpark). One perfect green work after another is Far Eastern General Construction Inc.'s practice of environmental sustainability, and they will continue to enhance their energy conservation and carbon reduction capabilities with innovative thinking, becoming divine teammates in safeguarding the global climate.

#