09.2024 Cover Story

Focusing on Winning Asia Cement Corporation's Low Carbon Formula

Far Eastern Magazine / Editorial Room

As the threat of climate change intensifies, businesses are facing more unknown operational risks. To increase their competitive advantage, are there any other options besides engaging in resource wars? This issue's "Cover Story" introduces how Asia Cement Corporation is taking steady steps to focus on alternative raw materials for cement manufacturing and creating green business opportunities.

As the threat of climate change intensifies, businesses are facing more unknown operational risks. To increase their competitive advantage, are there any other options besides engaging in resource wars? This issue's "Cover Story" introduces how Asia Cement Corporation is taking steady steps to focus on alternative raw materials for cement manufacturing and creating green business opportunities. Turn waste into gold and start a recycled economy

Turn waste into gold and start a recycled economy As is well known, the cement industry is an energy intensive industry. Considering that the carbon emissions from raw material calcination account for 60%, fuel accounts for 35%, and electricity accounts for about 5% in the production process, Asia Cement Corporation aims to promote a recycled economy and become a leader in the green transformation of the cement industry. To achieve a recycled economy, the treatment of waste is crucial. It can not only assist in reducing waste, but also replace natural resources and reduce carbon emissions from raw materials and fuels. Since 2019, Asia Cement Corporation has actively strived for external resources and opportunities. First, it assisted in the disposal of domestic waste in Hualien County, obtained support from the local government, and then gradually applied for environmental protection permits for the reuse of a number of official waste and resource products through its excellent disposal performance.

As is well known, the cement industry is an energy intensive industry. Considering that the carbon emissions from raw material calcination account for 60%, fuel accounts for 35%, and electricity accounts for about 5% in the production process, Asia Cement Corporation aims to promote a recycled economy and become a leader in the green transformation of the cement industry. To achieve a recycled economy, the treatment of waste is crucial. It can not only assist in reducing waste, but also replace natural resources and reduce carbon emissions from raw materials and fuels. Since 2019, Asia Cement Corporation has actively strived for external resources and opportunities. First, it assisted in the disposal of domestic waste in Hualien County, obtained support from the local government, and then gradually applied for environmental protection permits for the reuse of a number of official waste and resource products through its excellent disposal performance.In addition to establishing good relationships with the public sector, given that the Hualien factory is located in the eastern part of Taiwan and is far away from the western industry that mainly produces waste, the high transportation costs have deterred many operators. Senior executives of Asia Cement Corporation personally led colleagues to visit one by one, demonstrating their abilities and sincerity. Through communication and integration, they understood each other's needs and successfully gained the trust of operators, striving for valuable cooperation opportunities.

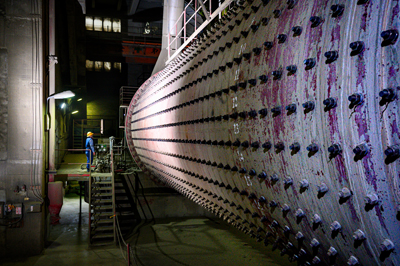

However, due to the significant differences in properties and poor fluidity between the waste generated by various industries and the materials used by cement plants in the past, it is difficult to transport them. In order to become a substitute for raw materials and fuels, additional or modified equipment must be added. To this end, Asia Cement Corporation has gathered colleagues in the fields of machinery, electronics, and manufacturing to develop feeding equipment, crushing and homogenization equipment, conveying systems, and calcination step furnaces, enabling different materials to be applied in the process, greatly improving waste treatment capacity and production efficiency, and becoming the cement industry with the most recycled economy material types used in Taiwan. On the other hand, the team is constantly improving the process equipment, such as extending the combustion time of the preheating machine's rising air duct, improving the heat recovery process of the cooling machine, and the boiler tube group for the exhaust waste heat of the preheating machine and cooling machine, gradually increasing the material usage and waste heat recovery efficiency of the recycled economy, thereby reducing energy consumption and carbon emissions in the clinker process.

At the same time, the headquarters and Hualien factory have respectively formulated the "Measures for Obtaining and Reusing Recycled Economy Raw Materials and Fuels" and "Recycled Economy Management Operating Procedures", and revised relevant SOPs to manage the acquisition and reuse of various recycled economy material sources, ensuring standardized processing procedures. At the same time, by participating in the revision meetings of waste reuse related regulations, actively providing revision opinions, increasing the number of cement industry projects that can be publicly announced for reuse, simplifying environmental application procedures, and accelerating the promotion of recycled economy.

Energy saving sustainable revenue synchronous growth

.jpg) According to statistics, from 2021 to 2023, Asia Cement Corporation assisted the government and various industries in processing approximately 1.08 million tons of waste and resource products, converting them into alternative raw materials and fuels for cement manufacturing, which is equivalent to reducing the consumption of natural resource ores and coal in the same amount of mining; In terms of greenhouse gas emissions, a total of about 270000 tons of carbon emissions will be reduced from 2021 to 2023, mainly due to Asia Cement Corporation replacing some limestone with various furnace slag and ash as alternative raw materials, reducing the heat consumption and carbon emissions required for the deacidification and decomposition of calcium carbonate into CaO, and replacing some fossil fuel coal with biomass containing wood chips, pulp and paper sludge, sewer sludge, and solid fuels as alternative fuels, achieving significant emission reduction results.

According to statistics, from 2021 to 2023, Asia Cement Corporation assisted the government and various industries in processing approximately 1.08 million tons of waste and resource products, converting them into alternative raw materials and fuels for cement manufacturing, which is equivalent to reducing the consumption of natural resource ores and coal in the same amount of mining; In terms of greenhouse gas emissions, a total of about 270000 tons of carbon emissions will be reduced from 2021 to 2023, mainly due to Asia Cement Corporation replacing some limestone with various furnace slag and ash as alternative raw materials, reducing the heat consumption and carbon emissions required for the deacidification and decomposition of calcium carbonate into CaO, and replacing some fossil fuel coal with biomass containing wood chips, pulp and paper sludge, sewer sludge, and solid fuels as alternative fuels, achieving significant emission reduction results.The sustainable actions of Asia Cement Corporation not only contribute to saving climate change, but also bring positive benefits to the company's revenue. From 2021 to 2023, the collection of waste disposal fees increased revenue by NTD 430 million, while reducing raw material procurement costs by NTD 150 million and fuel procurement costs by NTD 290 million, totaling NTD 870 million.

In addition to substantial profits, Asia Cement Corporation's performance in implementing low-carbon strategies has also been internationally recognized, sweeping multiple honors such as the TCSA Taiwan Corporate Sustainability Award and GCSA Global Corporate Sustainability Awards every year. In 2022, it was included in the "Taiwan Sustainability Index constant stock" by FTSE Russell, and in 2023, it won the "Green Leadership Award" at the ASIA Asia Responsible Entrepreneurship Awards three times.

Professional navigation challenges the future of AI

After the COVID-19 and the gradual recovery of national economies, the rise of carbon levy and AI technology has added many variables to the future business war. To this end, Asia Cement Corporation continues to improve its low-carbon technology in cement manufacturing. After optimizing clinker, it has developed and produced Portland limestone cement, masonry cement, and ternary mixed cement with lower clinker ratios to promote the low-carbon transformation of its products. At the same time, it has also partnered with Industrial Technology Research Institute to develop "Carbon Capture and Utilization Technology", Utilization, CCU」 By utilizing the technology and application of industrial waste re carbonation, and utilizing the principle of supergravity, industrial waste such as converter stones and waste concrete are combined with carbon dioxide in the flue gas of cement production processes to generate regenerated pellets, replacing natural pellets. It is worth mentioning that this recycled aggregate has the characteristic of negative carbon emissions, and the concrete it produces can achieve the effect of low-carbon, even negative carbon concrete. In the future, it is expected to cooperate with its subsidiary Ya Tung Ready Mixed Concrete Corporation and related downstream industry chains to reduce the carbon content of concrete.

In addition to pursuing high-quality process standards, Asia Cement Corporation has also established a "Sustainability Promotion Committee", with K. Y. Lee President serving as the Section Chief and managing ESG related issues in groups. For example, the "Net Zero Emissions Group" is responsible for collecting public opinion or conducting data research on topics such as recycled economy, net zero strategy, renewable energy, product innovation, and biodiversity. Through clear division of labor and system, each group decides on various implementation goals through sufficient discussion, and regularly inspects the effectiveness of implementation in the "Sustainability Promotion Committee". Through the P (Plan), D (Do), C (Check), A (Act) cycle, the company's decision-making and implementation units are ensured. The forward direction is consistent.

Following the company's low-carbon transformation strategy, Asia Cement Corporation independently develops construction methods, upgrades equipment, and forms alliances with local governments and businesses to transform traditional cement manufacturing plants into key industries such as chain steel, pulp, stone, petrochemicals, photovoltaics, semiconductors, and waste disposal. This transformation transforms seemingly insignificant waste into highly cost-effective alternative materials, reducing significant natural resource consumption and carbon emissions. Asia Cement Corporation is an indispensable driving force for Taiwan's development of a recycled economy, and the recycled aggregates and various low-carbon cement products under development are green new tools for driving profits in the future, taking Asia Cement Corporation one step closer to its vision of sustainable operation.

#