07.2024 Office Talk

Ya Tung Ready Mixed Concrete Corporation - Digital Transformation of Black Hand Industries

Ya Tung Ready Mixed Concrete Corporation / Pan Yichong

In the eyes of the general public, the ready mixed concrete industry is mostly a representative of "black hands", belonging to the 3K (dangerous, dirty, and laborious) industry, which is difficult to associate with digitization, automation, and intelligence; But Ya Tung Ready Mixed Concrete Corporation, under the call of Douglas Hsu and the leadership of K. Y. Lee Chairman and President Kim Chong jen, is embarking on a digital transformation plan, hoping to change the general perception of the ready mixed concrete industry and prove that traditional black handed industries can also be transformed into high-tech intelligent industries.

In the eyes of the general public, the ready mixed concrete industry is mostly a representative of "black hands", belonging to the 3K (dangerous, dirty, and laborious) industry, which is difficult to associate with digitization, automation, and intelligence; But Ya Tung Ready Mixed Concrete Corporation, under the call of Douglas Hsu and the leadership of K. Y. Lee Chairman and President Kim Chong jen, is embarking on a digital transformation plan, hoping to change the general perception of the ready mixed concrete industry and prove that traditional black handed industries can also be transformed into high-tech intelligent industries.Digital transformation can be divided into three stages: digitization, digital optimization, and digital transformation. Ya Tung Ready Mixed Concrete Corporation began to move towards digitization in 2020 (initial stage), establishing quality management apps, eTag vehicle management, smart energy management, temperature and humidity monitoring, air quality monitoring, etc; Subsequently, entering the digital optimization (development phase), using POWER BI to set up the Ya Tung Ready Mixed Concrete Corporation battle room, importing RPA, and significantly improving data consolidation efficiency. In 2023, the system will be officially launched and gradually expanded in functionality. Expected to complete digital transformation by 2030. The following is an introduction to the construction of relevant systems.

1. Quality Management App

In the past, quality management relied on manual work. After the quality control personnel completed the relevant operations, they recorded them in a form and only entered numerical values into personal computers after work or before leaving work. Due to the nature of the work, it is often only when inputting numerical values that problems such as paper damage, dirt, or unclear handwriting are discovered.

The newly established quality management system can be used on various smart handheld devices such as personal computers, laptops, PADs, and mobile phones to obtain real-time, fast, accurate, and efficient quality management data related to various concrete raw materials, materials, semi-finished products, and finished products (such as sampling records, test records, test body records, and test body management), and analyze them to generate various test reports, data curves, etc. After the data gradually accumulates, complex functions such as induction and comprehensive comparison can be performed.

2. Vehicle management

2. Vehicle managementVehicle management is a major challenge, including scheduling management, driver management, vehicle management, etc. Ya Tung Ready Mixed Concrete Corporation has established millimeter wave blind spot radar detection, alcohol detection cloud management system, eTag detection management system, and developed more eTag applications, especially in the deep application of eTag detection management system, which is divided into the following three major systems.

A. Vehicle return scheduling system: In the pre mixed concrete industry, the scheduling of vehicles is closely related to the driver's salary, including the number of trips carried, as well as the customers, construction sites, areas or distances carried. To ensure fairness, the industry usually adopts the "First In First Out" principle to avoid unfair human scheduling.

B. Vehicle Unloading Inspection System: Vehicles must be loaded into different mixers, so an eTag sensor is installed at the unloading point of the mixer. After successful sensing, the vehicle number, time, and other information are sent to the database through the Web Service developed by Ya Tung Ready Mixed Concrete Corporation for the shipping system to read and compare, in order to confirm compliance with the dispatcher's arrangement and avoid the impact on construction quality and company reputation caused by driver negligence, entering the wrong mixer for loading, loading the wrong materials, or delivering the wrong customer or construction site.

C. Vehicle weighing and verification system: Install an eTag sensor and two large outdoor LED displays on the weighing scale. When the vehicle stops, the eTag detection is successful. One LED display will display the weighing time and vehicle number, while the other LED display will display the total weight of the vehicle. At the same time, the weighing time, vehicle number, and total weight will be transmitted to the shipping system. The dispatcher can deduct the empty weight of the vehicle based on the concrete mix proportion content to confirm whether the net weight matches. Once the weight error exceeds 5% (the setting can be modified), the system will display an exception; If the weight is too light, it must be reloaded; On the contrary, if the weight is too heavy, the relevant measuring equipment must be rechecked or corrected.

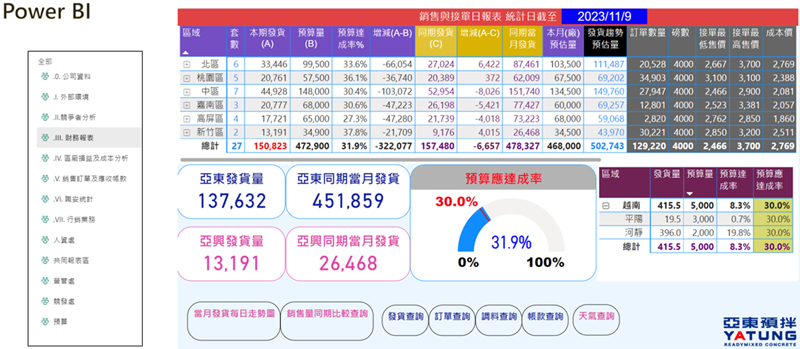

3. Ya Tung Ready Mixed Concrete Corporation Situation Room

3. Ya Tung Ready Mixed Concrete Corporation Situation RoomAt the beginning of the scenario room planning, the team considered whether to outsource. After internal discussions, they believed that the use of Power BI was not difficult, and outsourcing was expensive and took a long time to develop, making it difficult to achieve quick results. Therefore, they decided to build it themselves. Ya Tung Ready Mixed Concrete Corporation dispatched personnel to participate in the Power BI course offered by the group's human resources training center. Due to previous self-learning and the guidance of the instructors, they were able to quickly complete tasks assigned by the management team.

Considering that the users of the War Room are high-level managers, the team first conducted multiple interviews to understand President Jin's ideas and needs. After that, the War Room was planned into multiple topics and presented in different reports, starting with the simplest report and gradually establishing a complete report.

The EIS (Executive Information System) operation management system built with Power BI controls the operational performance of the entire company's 21 factories in Taiwan and 2 factories in Vietnam, including external environment, competitor analysis, financial statements, operation management, sales orders, accounts receivable, regional factory profit and loss cost analysis, occupational safety, marketing, human resources, quality management, and other projects, all of which are included in digital management.

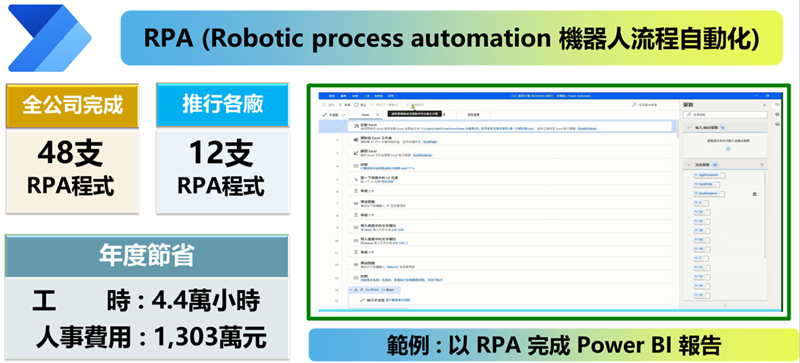

4. Import Robot Process Automation (RPA)

4. Import Robot Process Automation (RPA)RPA can assist employees in automating repetitive tasks, improving efficiency, and designing personalized automation processes through cloud and desktop processes. To encourage employees to install and use RPA, the original factory Acer Information and Ya Tung Ready Mixed Concrete Corporation each conducted 8 educational training sessions, arranged 300 trainees, and held a proposal competition.

Out of 40 proposal units, a total of 48 proposals were proposed, covering various applications such as business, production, quality management, information management and summary, report generation, automatic mailing, forwarding Line, automatic document OCR, and collection of external environmental information. The results were remarkable. In addition to the group award, a total of ten teams received bonuses, and the Gold President specially awarded three individual learning awards.

It is worth mentioning that the application of RPA did not end due to the proposal competition. The company selected 12 programs from the proposals as daily applications, assisted colleagues in compiling reports, collecting external information, and notifying relevant personnel on a daily basis. It is estimated that 44000 hours of labor can be saved annually, and the personnel cost is NTD13.03 million.

Although pre mixed concrete belongs to the traditional industry, Ya Tung Ready Mixed Concrete Corporation, under the leadership of President Jin, introduces technological technology for operation and management. Through the deep application of eTag, it manages vehicle scheduling, cutting, and weight inspection. It also uses Power BI's self built supervisory information system - EIS Situation Room, sets up a complete App quality management system, and uses IoT Internet of Things (IoT) technology to implant sensors in the bonding material storage tank, check the moisture content of sand and gravel, upload them to the cloud in a timely manner. Smart Rock is used to predict and control the surface temperature, new surface temperature difference, and maturity of concrete, in order to grasp the situation. Its strength development provides customers with high-performance concrete (HPC) and low-carbon green building materials products.

The Global Cement and Concrete Association (GCCA) points out that concrete is an indispensable key material for building modern society, and its future should be based on sustainable development. Ya Tung Ready Mixed Concrete Corporation recognizes high-quality, high-tech, and high-performance human resources as the engine of enterprise competitiveness. Therefore, with "Technical Oriental Petrochemical (Taiwan)" as the main axis, it has set three major goals to continuously develop high-performance concrete and low-carbon products, establish a digital production and transportation management system, and promote the full cycle of concrete towards carbon neutrality.

#