12.2024 Group Briefing

Far EasTone Telecommunication and Chiahui Power Corporation collaborate to pioneer 5G/AI tower inspection

Far Eastern Magazine / Editorial Room

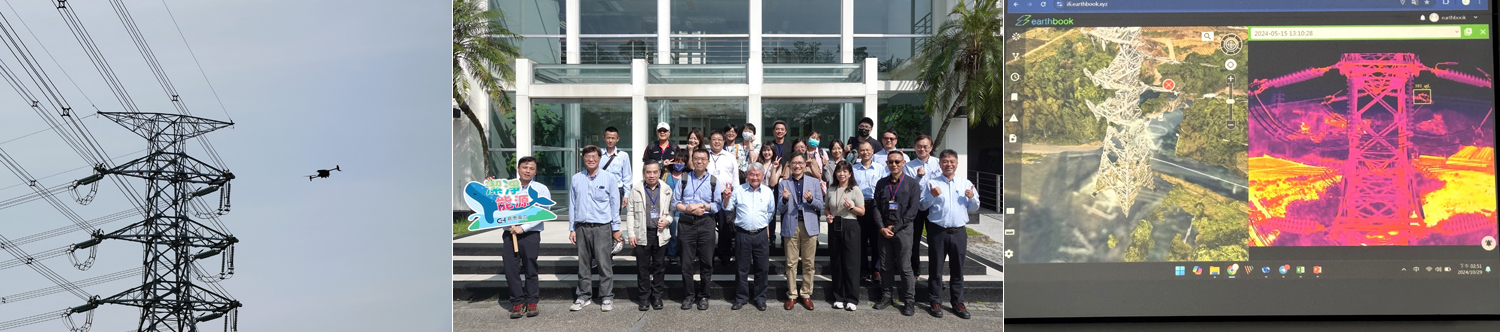

Chiahui Power Corporation announced on October 30th that it has partnered with Far EasTone Telecommunication to introduce an unmanned aerial vehicle (UAV) automatic inspection solution based on 5G private network combined with AI technology, which will be applied to the inspection of transmission and distribution lines in high-voltage power towers. This not only improves inspection speed and accuracy, but also effectively reduces the risk of personnel performing high-altitude operations without power outages, providing strong guarantees for the safe and stable operation of the power system.

Chiahui Power Corporation announced on October 30th that it has partnered with Far EasTone Telecommunication to introduce an unmanned aerial vehicle (UAV) automatic inspection solution based on 5G private network combined with AI technology, which will be applied to the inspection of transmission and distribution lines in high-voltage power towers. This not only improves inspection speed and accuracy, but also effectively reduces the risk of personnel performing high-altitude operations without power outages, providing strong guarantees for the safe and stable operation of the power system.Li Jianzheng, Vice President of Far EasTone Telecommunication Enterprise and International Business Group, stated that in the face of industry shortage and increasing awareness of work safety, coupled with the vast area and difficult management of power plants, Far EasTone Telecommunication is honored to assist Chiahui Power Corporation in building a fully automated unmanned aerial vehicle tower inspection system with rich experience in 5G enterprise private network construction and integration. By combining 5G high-definition image transmission with AI recognition, real-time interpretation and decision-making assistance, efficiency is improved while reducing work safety risks, achieving smarter, more sustainable, and resilient power operations.

President Chen Guangtai of Chiahui Power Corporation also pointed out that modern power management not only requires advanced technology, but also forward-looking thinking. The cooperation between the two parties in implementing the 5G/AI unmanned aerial vehicle automatic inspection scheme has strengthened the efficiency of power inspection, significantly reduced work safety risks, and achieved a major breakthrough in technological innovation and smart power management. This practice of the company's commitment to sustainability development also contributes to promoting energy transformation.

Chiahui Power Corporation is the largest privately-owned natural gas power plant in Taiwan, with a total capacity of 1.21 million kilowatts and an annual power generation of over 5.67 billion kilowatt hours, supplying electricity to more than 1.18 million households. It is extremely important to regularly inspect and maintain transmission lines in order to maintain stable electricity consumption for people's livelihood and industry. The traditional manual inspection method relies on maintenance personnel cutting off power in a high-voltage environment, climbing and wiring to inspect, which is not only time-consuming and labor-intensive, but also highly dangerous. Through the unmanned aerial vehicle (UAV) fully automatic tower inspection system, efficient inspections can be carried out on vast factory areas, and it is equipped with dual thermal sensing lens cameras, which can complete shooting, identification, and reporting tasks based on the route planned in advance with a 3D model system. The image data obtained during the inspection process is synchronously transmitted to the monitoring center via the 5G private network for professional engineering personnel to analyze and interpret, quickly identify potential problems, and repair them in real time.

More importantly, drone inspections do not require power outages, ensuring that daily power supply is not affected. All images and data will be accumulated into a maintenance history database, achieving digital management and improving operational efficiency. In the future, AI drone technology will be further expanded to include factory inspections, facility detection and prediction, as well as all-weather barrier free work safety management mechanisms, making power plant management safer and more efficient.

#