06.2020 Honor and Personnel Change

Asia Cement Corporation has obtained three international standards at the same time, ranking the first in world's first cement industry

Asia Cement Corporation / Chen Congming

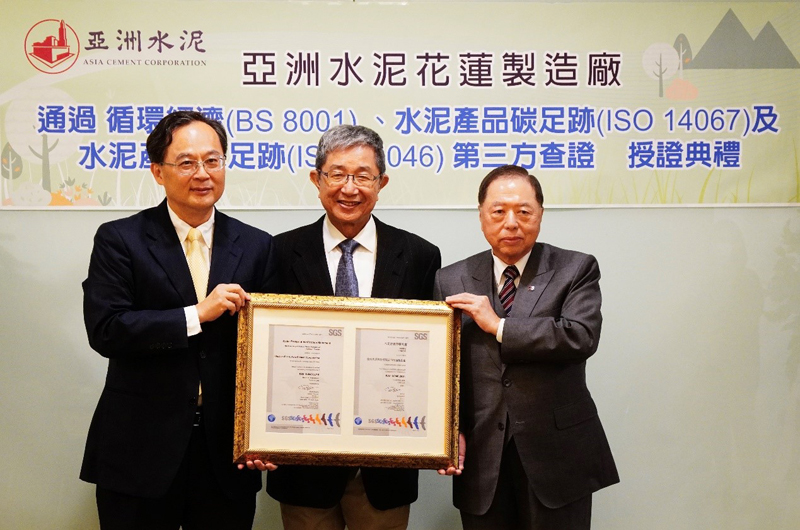

Asia Cement Corporation has been promoting green production process for a long time and is committed to focusing on recycled economy, energy saving and carbon reduction, and improving water resource utilization efficiency. On May 4, it announced that the Portland cement produced by Hualien plant of Asia Cement Corporation was internationally recognized. Through SGS verification, ISO 14067:2018 product carbon footprint standard and ISO 14046:2014 product water footprint standard were obtained, and optimizing level of BS 8001:2017 recycled economy business model maturity was gained as well, making it become the first cement company in the global cement industry to obtain recycled economy standard, carbon footprint and water footprint certification of cement products at the same time. Asia Cement Corporation President K. y. Lee accepted the license from Vice President Huang Shizhong of SGS, and Zheng Futian, Chairman of Taiwan Green Productivity Foundation attended the meeting as a witness. President K. y. Lee said that Asia Cement Corporation would not be complacent about this, and would continue to work hard to reduce the consumption of natural resources and greenhouse gas emissions, and contribute to the sustainability of environment.

Global carbon emissions are increasing year by year, and countries around the world pay more and more attention to the issue of carbon footprint. It is emphasized that the company has long established a complete coping strategy. In addition to assessing the risks and opportunities of climate change, it also uses advanced technology to voluntarily reduce greenhouse gas emissions. It fully discloses the emission through CDP and CSR. And it is the first cement manufacturer in Taiwan to check the carbon footprint of their products with the concept of life cycle from raw materials, processes to products, and actually do a good job in climate change management, which shows the intention to fulfill corporate social responsibility.

In the aspect of water resource utilization, Asia Cement Corporation has formulated water-saving plan and established systematic recycling mechanism to ensure that water resources are fully utilized and not wasted in the cement production process. According to the estimation, the water recycling rate of Hualien plant of Asia Cement Corporation is more than 85%, and the recycled water is about 6 times of the water intake. That is to say, every drop of water used by Hualien plant of Asia Cement Corporation in the cement manufacturing process is reused for 6 times.

The rotary kiln with high firing temperature is an important driving force of recycled economy in the cement industry, which can not only effectively remove waste, but also convert it into alternative raw materials and alternative fuels, and reduce the use of natural raw materials and fuels in the cement production process. In recent years, Asia Cement Corporation Hualien plant has made great efforts to become a recycling economy model plant. From the perspective of local enterprises, it gives priority to the needs of Hualien County, including stone powder of stone industry, incinerating recycled aggregate, pulp paper sludge. At the same time, it assists operators in other counties and cities to recycle wastes, such as using converter stone as alternative raw materials, which is the pioneer in Taiwan. Hualien plant of Asia Cement Corporation said that with the advantages of the characteristics of the cement plant, it will continue to make efforts in the future to help the local area, government and relevant industries to solve the problem of waste removal, create new value of cement industry, and continue to implement sustainable green home with advanced technology and the heart of loving the earth. Wei